Sustainable cooling water treatment

Sustainable cooling water treatment

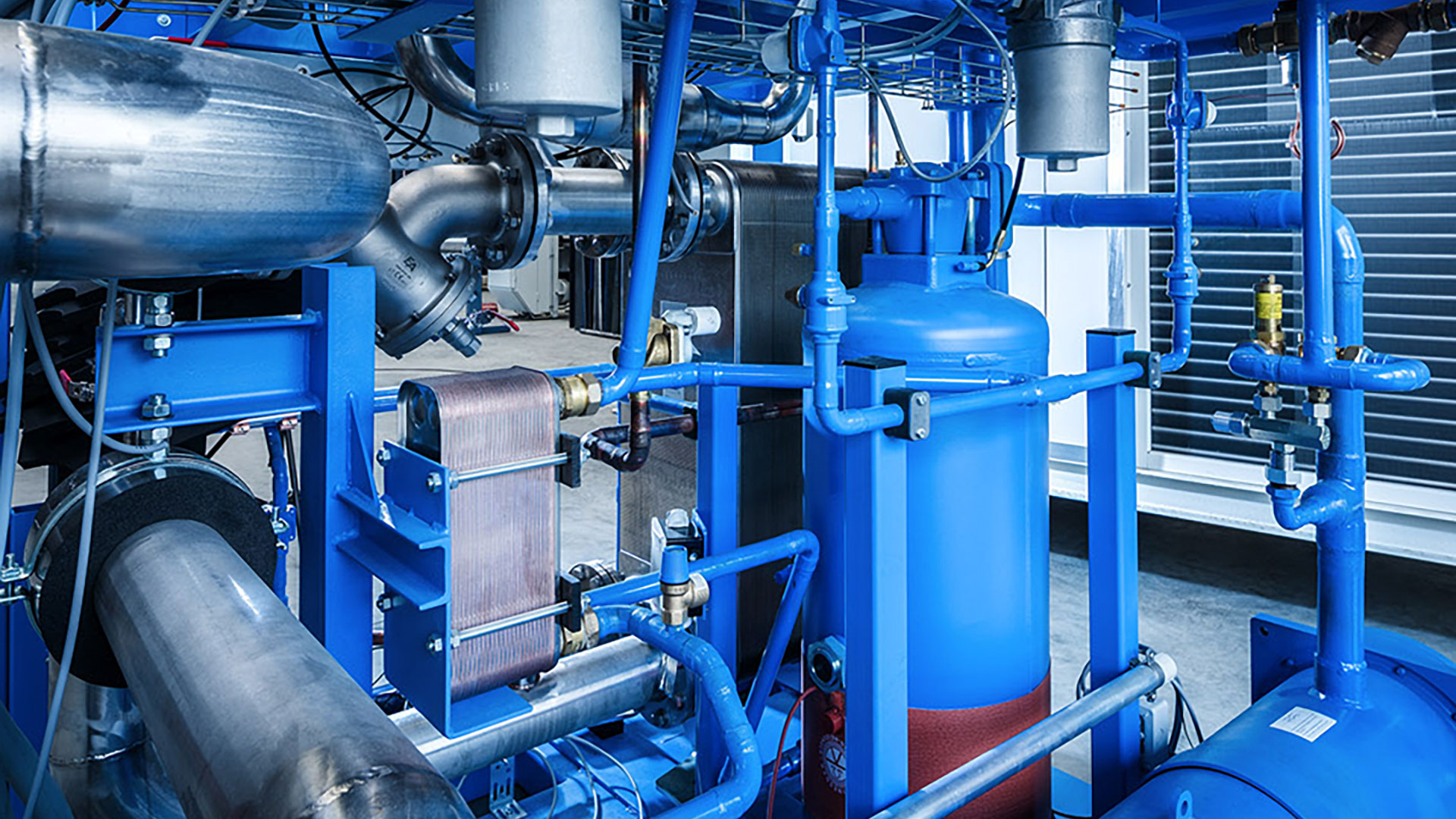

The PipeJet® process integrated in our Easy Clean System (ECS) enables permanent physical and CSR-compliant water treatment in machine and connected building systems (machine waste heat recovery).

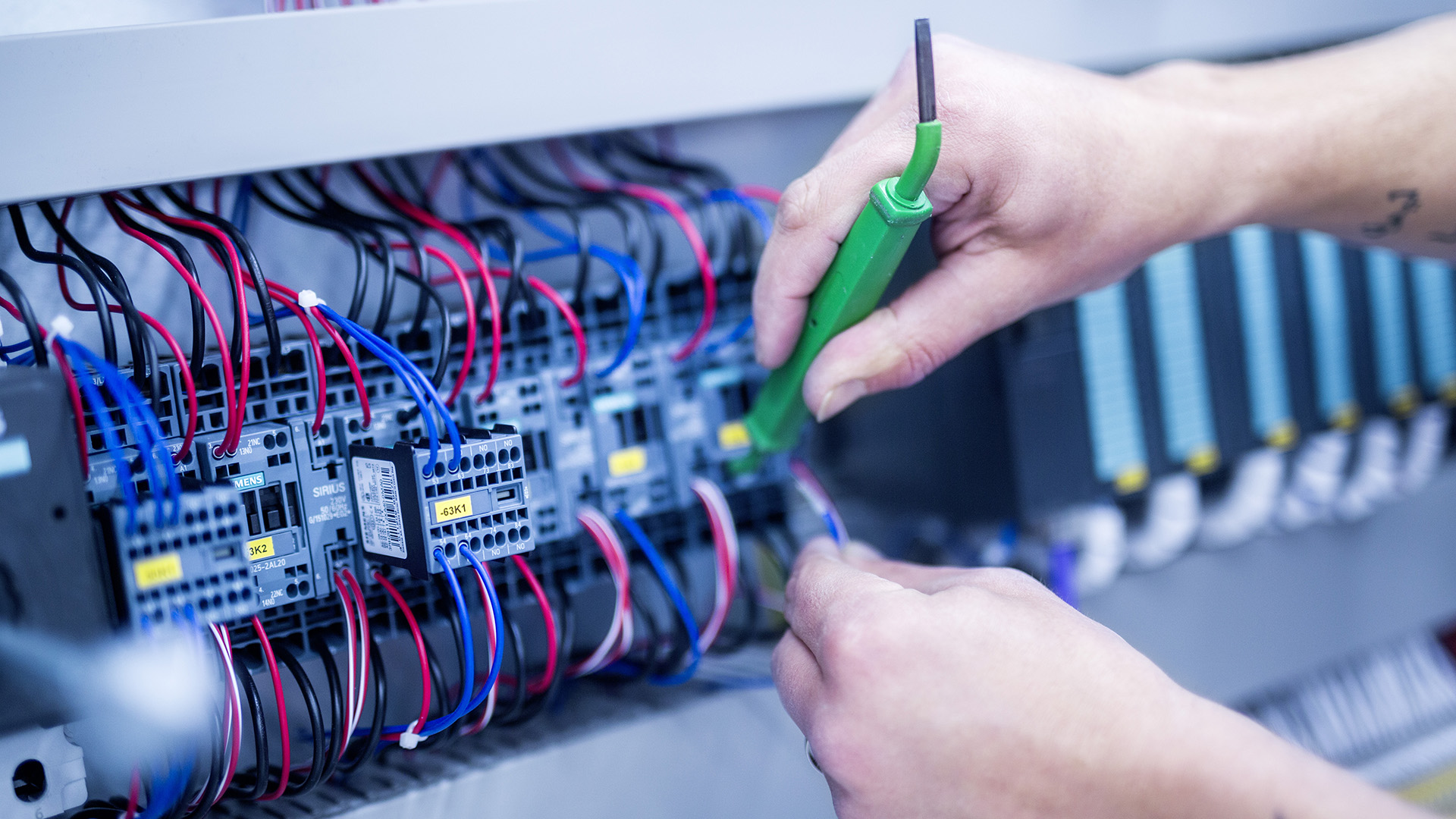

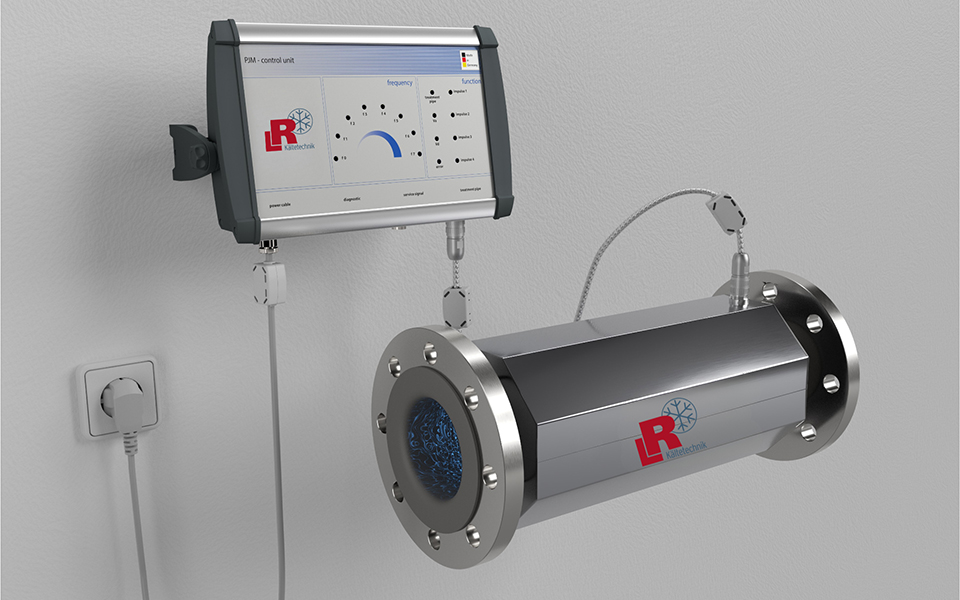

The L&R ECS system consists of a control unit for frequency-based pulse generation, the water treatment unit and high-performance filters.

The microprocessor-controlled electronics generates an alternating frequency band according to a special mathematical algorithm. With this pulse, an effective alternating-pulsating electromagnetic field is built up via the treatment unit in the entire interconnected water system. The absorption capacity of the cooling and heating water is significantly increased.

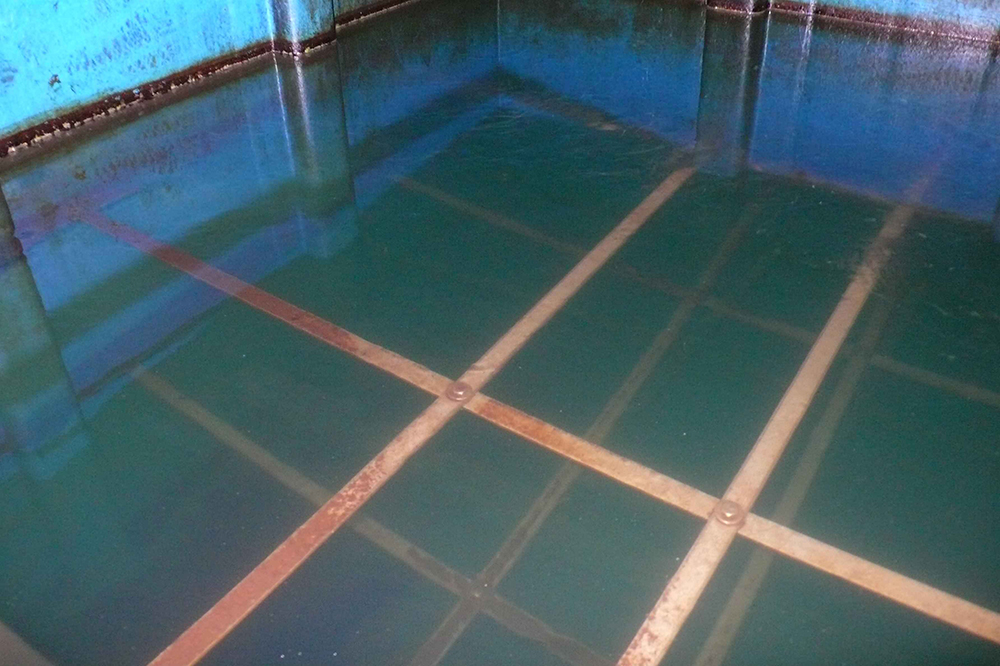

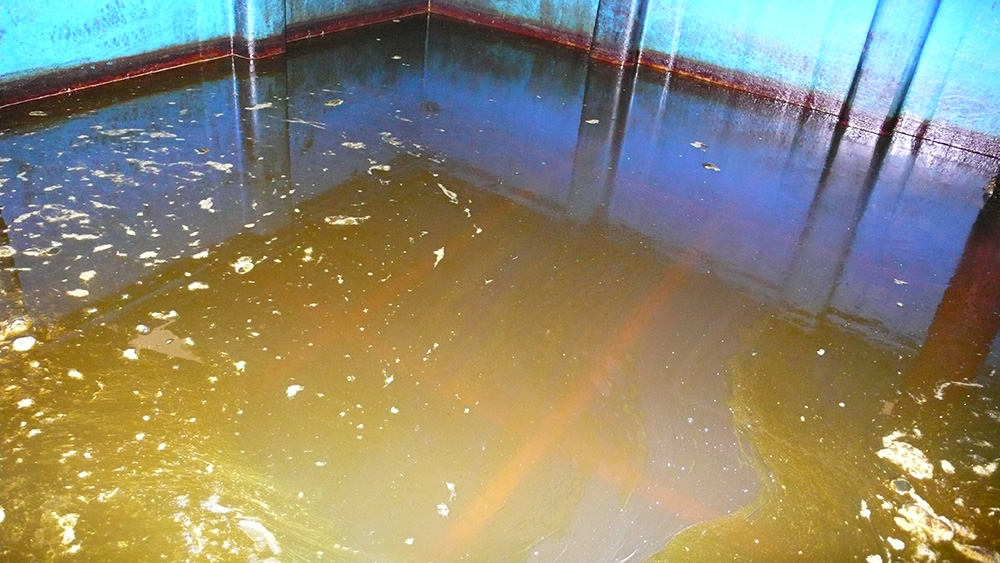

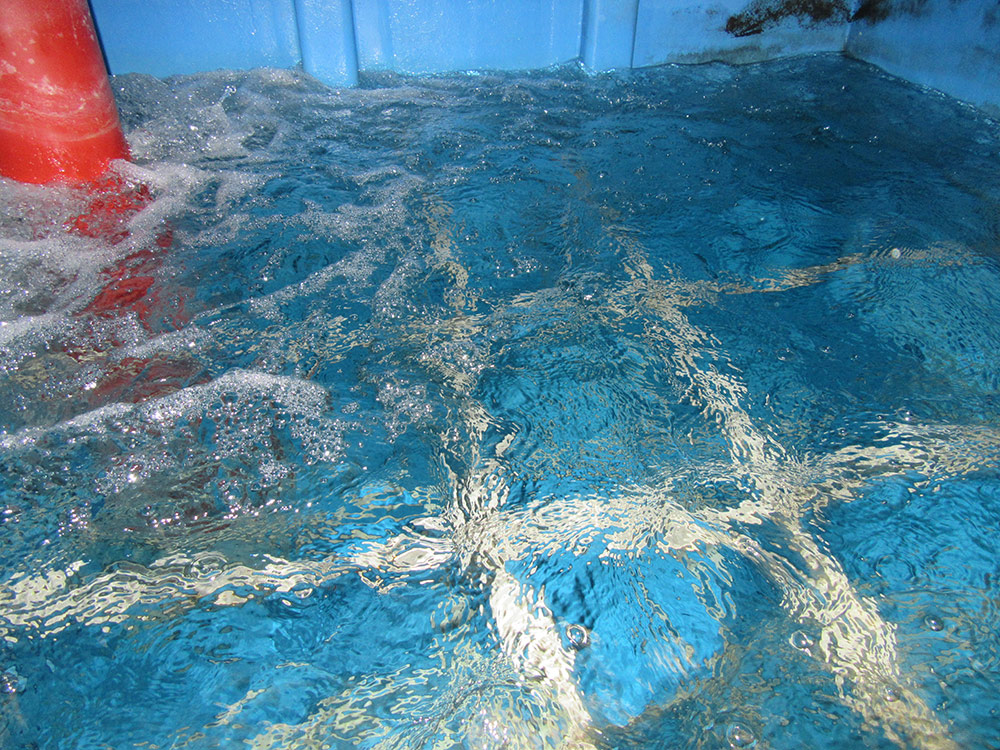

Crystalline structures scale/corrosion are detached, ingredients of the water no longer accumulate, biofilms dissolve and are filtered out in the connected high-performance filter system.

These technology components are specially developed for demanding industrial applications. In addition to low maintenance, they are characterized by a robust long service life and very good dirt retention. Apart from changing the filter elements of the high-performance filter required for this purpose, the ECS system is maintenance-free. Existing filter systems can be integrated as part of a constructive step filtration (see below).

The effect is an optimized cold and heat transfer. The sensor technology and thus the calibration of your machines work perfectly and permanently.

With the ECS you drive an effective and environmentally friendly system, which costs you only a fraction of a complete cooling water system renovation. You achieve a sustainable and permanent improvement of the water and thus cooling quality. In this way, you increase the service life of your systems and the utilization of your production.

Within 1 – 1 1/2 years the ECS system pays for itself. Budgeting for running costs such as electricity, gas/water, personnel, and machine usage can be calculated and used more cost effectively for your productivity.

The consequence:

Economical

- Stable, efficient production processes

- Consistent production quality

- High machine availability

- Low maintenance costs

- No or low recurring chemical costs

- Reduction of water, waste water and disposal costs

Sustainable

- Minimised consumption of resources

- No polluted waste water

- No polluted waste (filters or sludge)

- Safe handling (personal and machine protection)

- Reduced germ formation through biofilm removal

- Compliance with CSR standards in production (green factory)

After 10 years of experience in chemical-free treatment technology and with the constructive support of our customers, L&R Kältetechnik has developed, tested, and brought the Easy Clean System to series production readiness. In the meantime, the ECS has been installed as a standardized cooling water treatment system in numerous cooling plants and is referenced by our customers. The Easy Clean System is tailor-made for your application.

References from well-known customers are available on request.

Your contact partner for H₂O technology –

natural water treatment

GREGOR HEIERMANN

WATER TREATMENT SYSTEMS SALES

Phone +49 2935 9652-210

g.heiermann@lr-kaelte.de