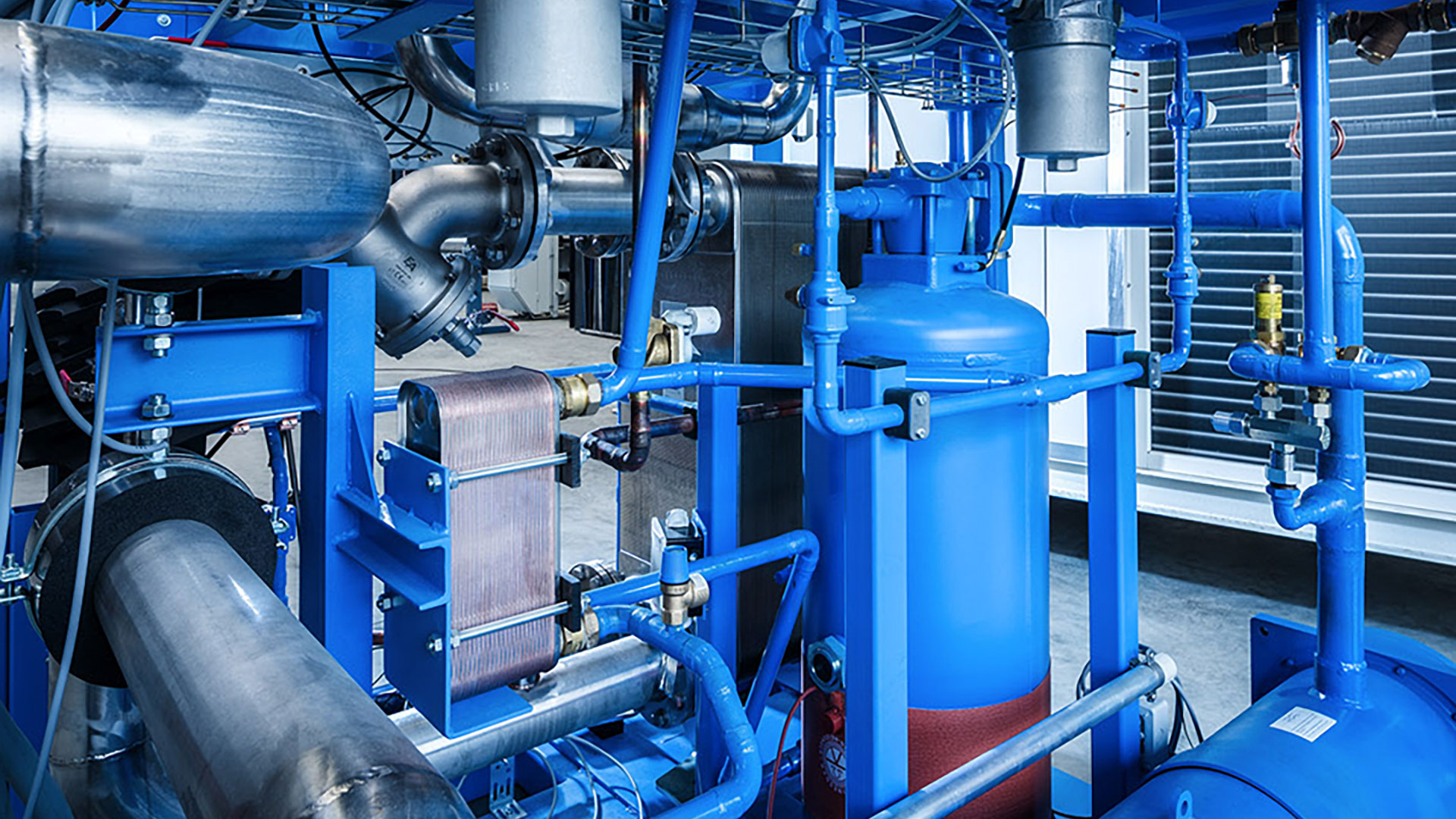

For the main plant at WHW Hillebrand Group’s facility in Wickede, Westphalia, L&R Kältetechnik GmbH & Co. KG has planned and installed a refrigeration system that sets the standard in terms of energy efficiency thanks to its ultra-modern technology. In addition, the system impresses with its simple operation and visu-alisation via a touch panel.

“We look at the black side”: When the WHW Group makes this claim, it is not express-ing a pessimistic attitude. On the contrary, this slogan refers to the coating technolo-gies that WHW offers. The group is one of the largest European coating companies for cathodic corrosion protection with zinc, zinc-alloy, duplex and organic coatings. Products coated with these materials are typically black in appearance.

Special know-how also in efficient use of energy

WHW has acquired special know-how in the finishing of high-quality components with zinc-nickel alloys. In this regard, the company – which was founded in 1937 and now operates from four locations – claims to be the largest and most efficient supplier of mass-produced items.

WHW is also far ahead in terms of its efficient use of resources. At the Wickede site, the company’s own combined heat and power plant, fuelled by renewable raw materials, generates thermal energy for its production processes. And WHW relies on the latest energy-saving technologies not only for heating technology, but also for generating the cold required for its processes. A highly efficient refrigeration system is used here, which was planned, built and installed by L&R Kältetechnik GmbH & Co.

Energy saving: Variable condensing temperature control

A chiller with a total capacity of 700 kW cools the process water to 20 °C and ensures constant bath temperatures within narrow tolerance limits. It operates using the refriger-ant R 134a and is equipped with a “VariKon” controller. This is the name of the energy-saving technology offered by L&R, in which the condensation temperature is automati-cally and flexibly adjusted to the current outside temperature.

This type of control allows for energy savings on a considerable scale. To explain this, a comparison with conventional refrigeration systems is necessary. These types of systems are operated at a fixed condensing temperature, usually around 47 °C or 48 °C. However, this temperature is only required in the case of very high outside tempera-tures of approx. 35 °C or higher, meaning that conventional systems always operate based on a worst-case refrigeration scenario.

The VariKon controller, on the other hand, detects the current outside temperature and reduces the condensation temperature of the refrigeration system according to the outside temperature. For example, the L&R chiller requires a drive power of 134 kW at a condensing temperature of 47 °C (and an outside temperature of 35 °C). At a condens-ing temperature of 29 °C, which is sufficient for an outside temperature of 17 °C, the power consumption is only 66.2 kW. This is a reduction in drive energy of 68 kW, or more than 50%. In this way, the system saves energy every day. Accordingly, the coef-ficient of performance increases as a measure of how efficient the system is.

Winter relief as a further energy-saving measure

What’s more, the new refrigeration system at the WHW plant in Wickede is equipped with an additional free cooling unit that supports cooling at outside temperatures lower than the return temperature, thus relieving the refrigerating machine and saving drive energy. With outside temperatures of less than or equal to 15 °C, the free cooling unit can even provide the complete cooling capacity. The refrigeration machines are then switched off and the “cold is obtained exclusively from the environment”. This technology is called “winter relief” (free cooling). Winter relief is realised by a self-draining free cooling unit, which is automatically emptied when the machine is at a standstill. The plant is operated without the addition of glycol and therefore also meets high environmental standards as well as the requirements of the German Federal Water Act (Wasserhaushaltsgesetzes, WHG).

High cost savings, short payback time

During the joint planning phase, L&R showed the responsible persons at WHW Hille-brand exactly what savings effect could be expected if both proposed technologies – variable condensing temperature control and “winter relief” – were implemented. Assum-ing 6,000 operating hours per year and an electricity price of €0.12/kWh, this results in annual energy cost savings of over €122,000. This means that investing in ultra-modern, energy-saving refrigeration technology “pays for itself” within a manageable period of time.

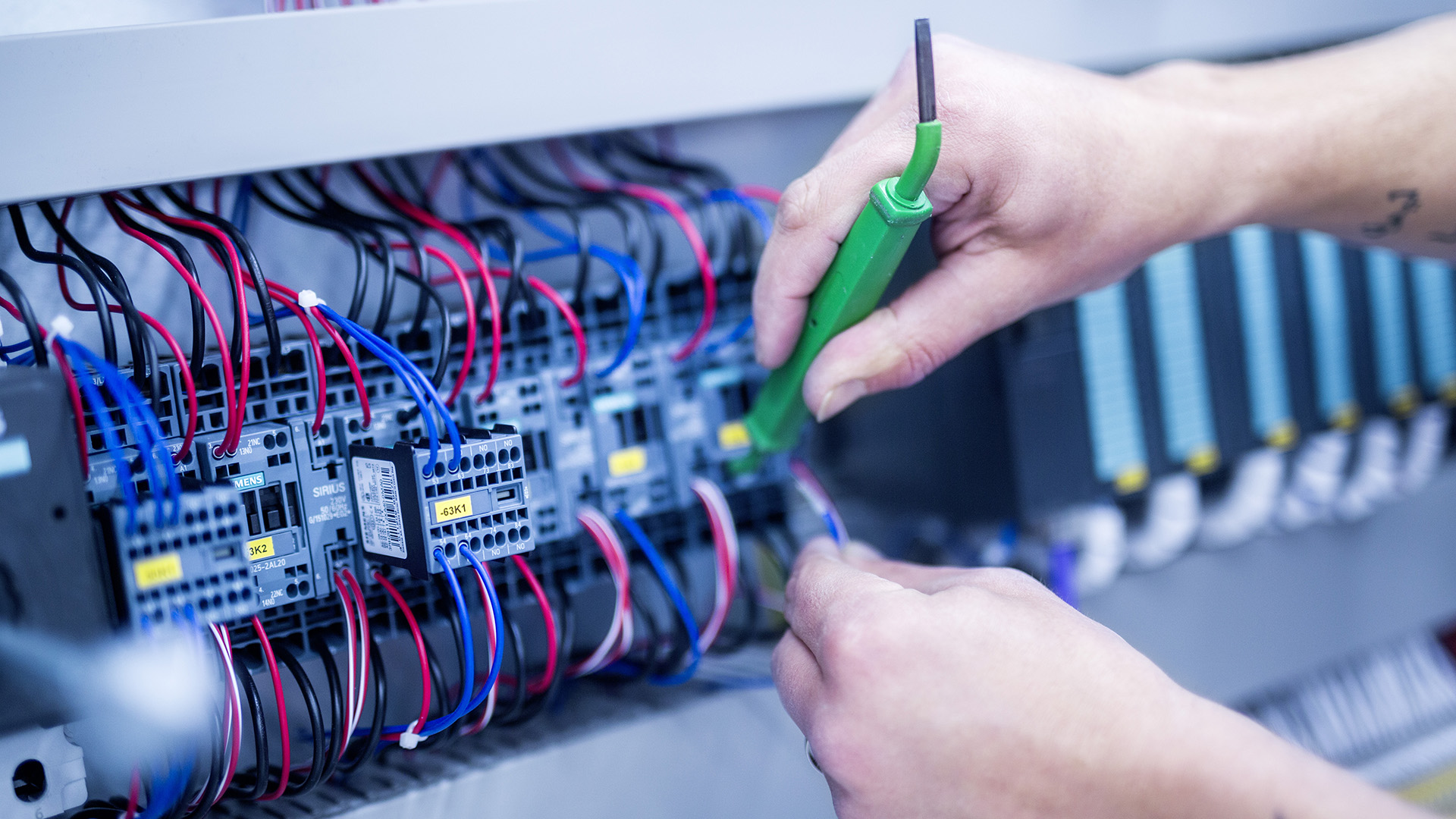

Transparency of the human-machine interface

In the meantime, L&R technicians have installed and commissioned the refrigeration system, and the customer is completely satisfied – also with the efficiency of the system. In addition, the operating technicians at the WHW plant benefit from the transpar-ency of the human-machine interface: A touch panel visualises the system functions and allows quick adjustment of central parameters. All functions of the refrigeration system are controlled and monitored by a PLC. L&R traditionally handles PLC pro-gramming in-house, as well as control cabinet construction, which has recently been significantly expanded.

You can find more information about the company at www.lr-kaelte.de