A specialist in cold forming special steel and titanium has commissioned a new cooling tower system. It supplies cooling water for various process steps, such as cooling after rolling and heat treatment. The new system is characterised by a high degree of operational reliability and energy efficiency.

Stainless steel is not only a sought-after material in mechanical and apparatus engineering, but also in medical technology. Within the extensive range of special (stainless) steels, there are special surgical steels, from which instruments such as scissors and clamps are made. In addition, special grades are available for surgical needles or fast rotating instruments. The requirements for stainless steels implanted in the human body – for example, in dental and spinal surgeries as well as in protective surgical procedures after accidents – are particularly high.

Temperature controlled processes

A German company that manufactures semi-finished products from such special steels (and supplies them mainly to the medical technology sector) covers the entire cold forming process chain at its production plant from rolling, various types of heat treatment and finishing, to cutting to length. Several of these processes occur under the influence of temperature, for example, rolling and, as a hardening process, annealing. Precise temperature control during subsequent cooling is also decisive for the quality of the end products.

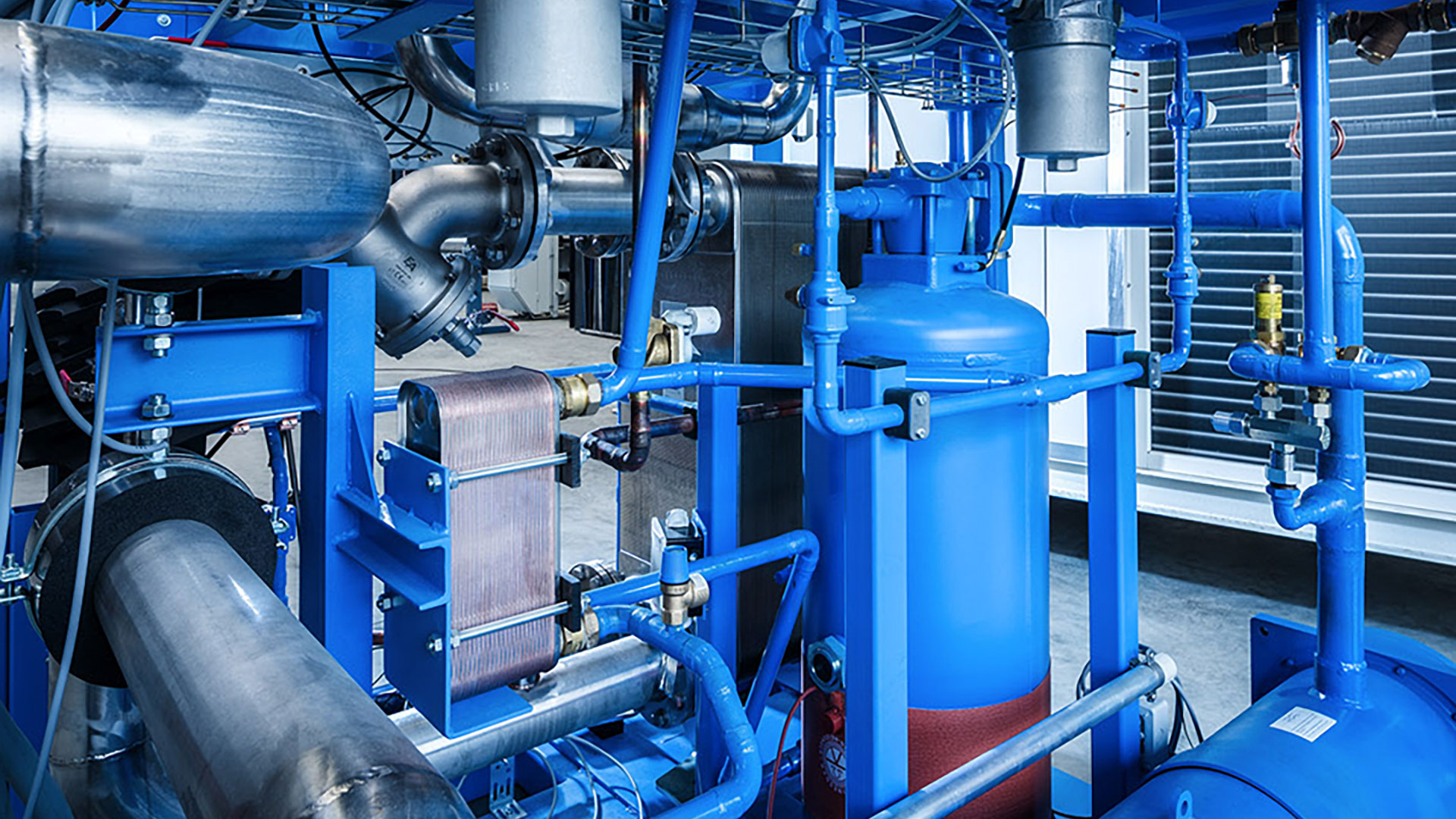

For this plant, L&R Kältetechnik GmbH & Co. KG, which has extensive experience with similar projects, designed a tailor-made cooling system. It cools the 35 °C water coming from the return flow on the plate heat exchangers for the rolling stand and annealing shop down to 25 °C and feeds it back into the cooling circuit. More than 200 m3/h of cooling water are in circulation.

High operational reliability, low noise, very good energy efficiency

The L&R refrigeration system consists of two separate cooling tower cells, each with a cooling capacity of 1,150 kW. The advantage of this concept is its higher operational reliability: If one cell fails, the other can cool the central production facilities. In order to achieve a high degree of energy efficiency,

the cooling towers use double-sided, low-pressure, high-performance fans that are highly efficient and feature low noise levels. The fan drives are controlled in accordance with the actual demand. This leads to precise temperature control and, at the same time, to savings in drive energy.

The heat exchanger circuits are supplied by three consumer pumps, each with an output of 30 kW. Two pumps are designed as base load pumps with fixed speed and operate alternately. A third, speed-controlled pump takes over the peak load and the precise control. This ensures that the heat exchangers are supplied with re-cooled water in an exact, needs-based and energy-efficient manner.

“All inclusive” with desalination, corrosion protection and filter technology

The cooling system designed and installed by L&R is equipped with a desalination system to counteract the thickening process caused by water evaporation in the cooling tower, as well as with a system that continuously supplies the cooling water with a corrosion protection agent and biocide (against biological infestation).

Since a cooling tower system is an open cooling system, in which the water comes into direct contact with the outside air, good water treatment and comprehensive filter technology are of great importance. For this purpose, the plant is equipped with a filter group for filtering out coarse particles (with differential pressure monitoring for controlling the degree of contamination) and with a sand filter system for filtering out fine particles. In this system, an automatic backwash device disposes of the dirt particles.

In order to reduce the amount of make-up water required for evaporation and blowdown, such a system can be further optimised by an upstream softening plant, depending on the quality of the make-up water. Together, all these measures ensure stable water quality.

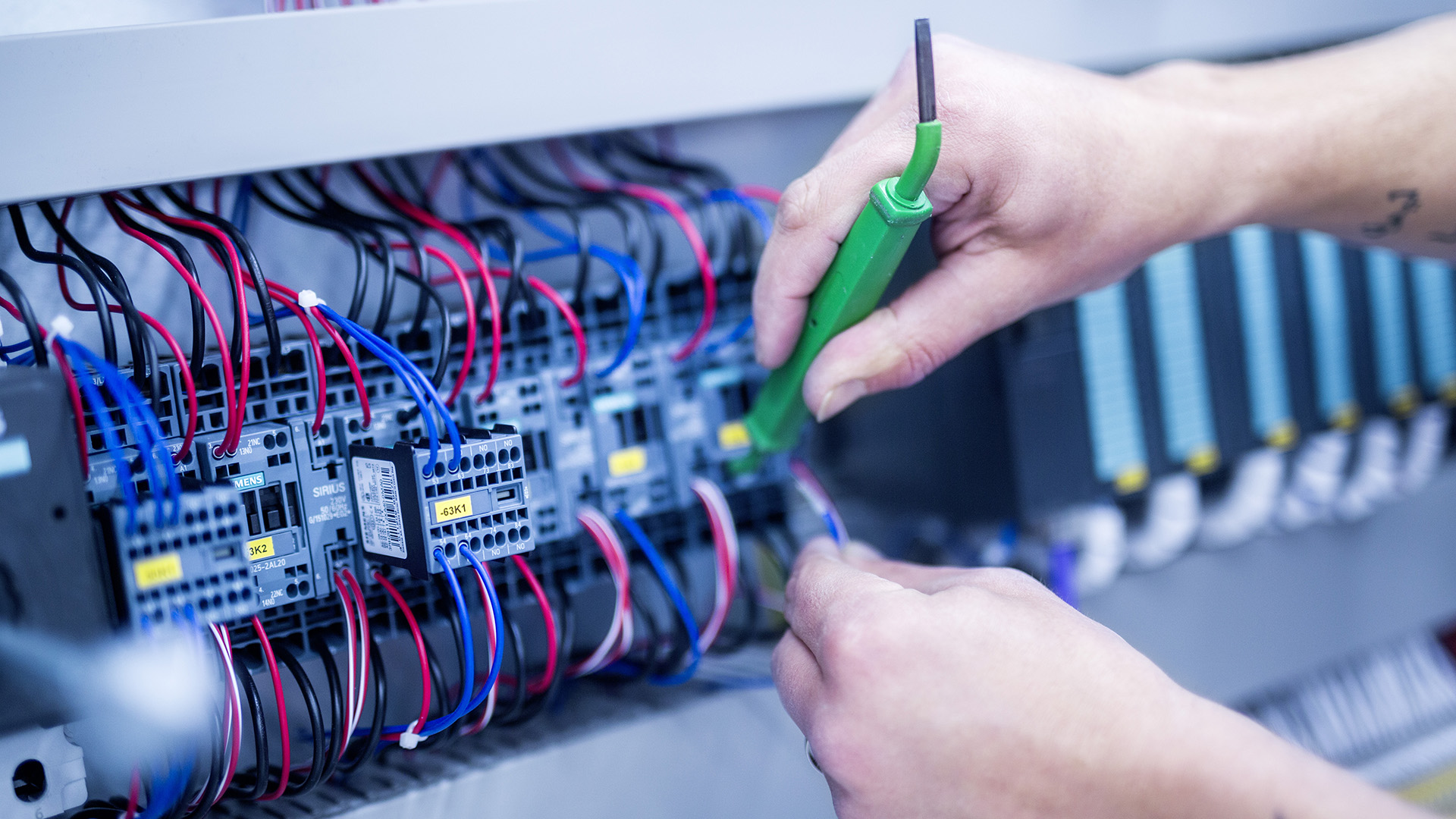

Control technology as a core competence

System components for maintaining water quality are also integrated into the central control technology, which is traditionally developed in-house at L&R and manufactured in the company’s own control cabinet construction. Operation via touch panel creates the necessary transparency for the human-machine interface.

Since its installation – which went smoothly – the system has been running to the operator’s full satisfaction. The special steel processor is now using a future-proof and energy-efficient refrigeration system to produce high-quality, semi-finished products.

Sector

Surface & electroplating technology

System solution

Cooling tower systems