Mobile warehouses for the pharmaceutical industry

Mobile warehouses for the pharmaceutical industry

30 years’ experience give you the edge in new challenges

This is how long L&R Kältetechnik has been developing concepts for ultra-low temperature applications. This is how long L&R Kältetechnik has been developing concepts for ultra-low temperature applications. They can be used to store vaccine sera (vaccines), blood plasma, human biological agents, sample material, chemical substances, reserve samples, stem cells, genomes, bacteria, bone marrow, biomedical materials, compounds, preparations, batches, drugs and medicines.

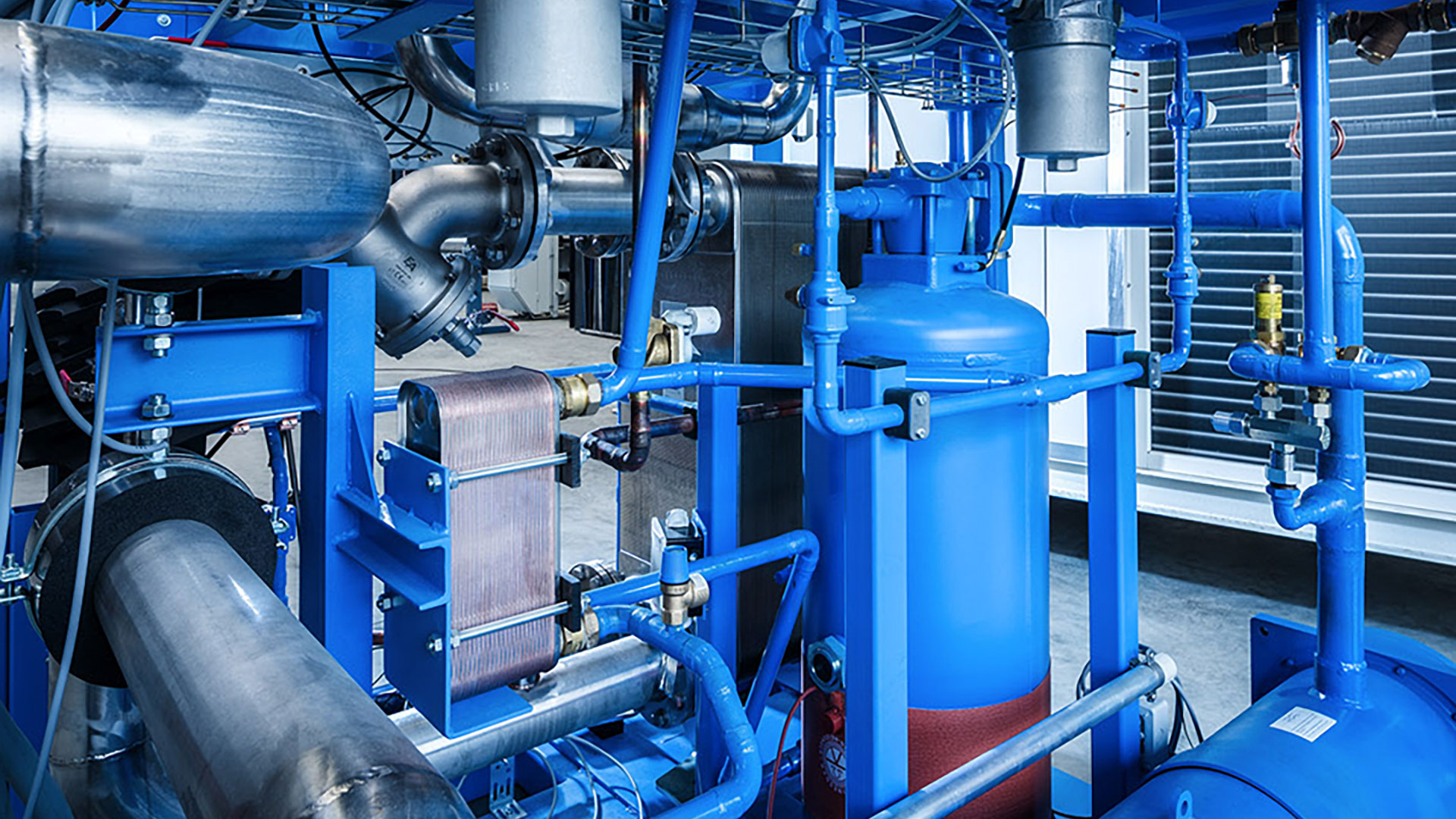

The fully autonomously operating ultra-low temperature containers are air-cooled, so only a power connection is needed for operation. Even if the power should fail, the optional emergency power supply or even nitrogen emergency cooling (LN2) offers maximum safety.

In direct comparison, frequently used laboratory freezers have significantly higher operating costs, use more floor space and have a high demand for (re)calibration/(re)qualification, owing to their principle of operation.

The details make the difference

With a temperature difference of over 100 K between the external environment and the inside of the refrigerated container, it is easy to imagine that the direct influence on the stored product when the door is opened, without a pre-cooling room that works as an airlock, so to speak, has an undesirably high impact on the quality of the goods.

In addition, at a temperature of -20 °C, the airlock causes a high level of air dehumidification, so in the -80 °C range, on the one hand, the defrosting capacity and therefore the heat input is reduced and, on the other hand, the typical freezing effects (such as slippery floors and icy fans) are reduced. In order not to expose sensitive, expensive goods to any danger, redundant systems are used as standard. Therefore, if a malfunction occurs within a refrigeration circuit or the associated control system, the system automatically switches to the second system.

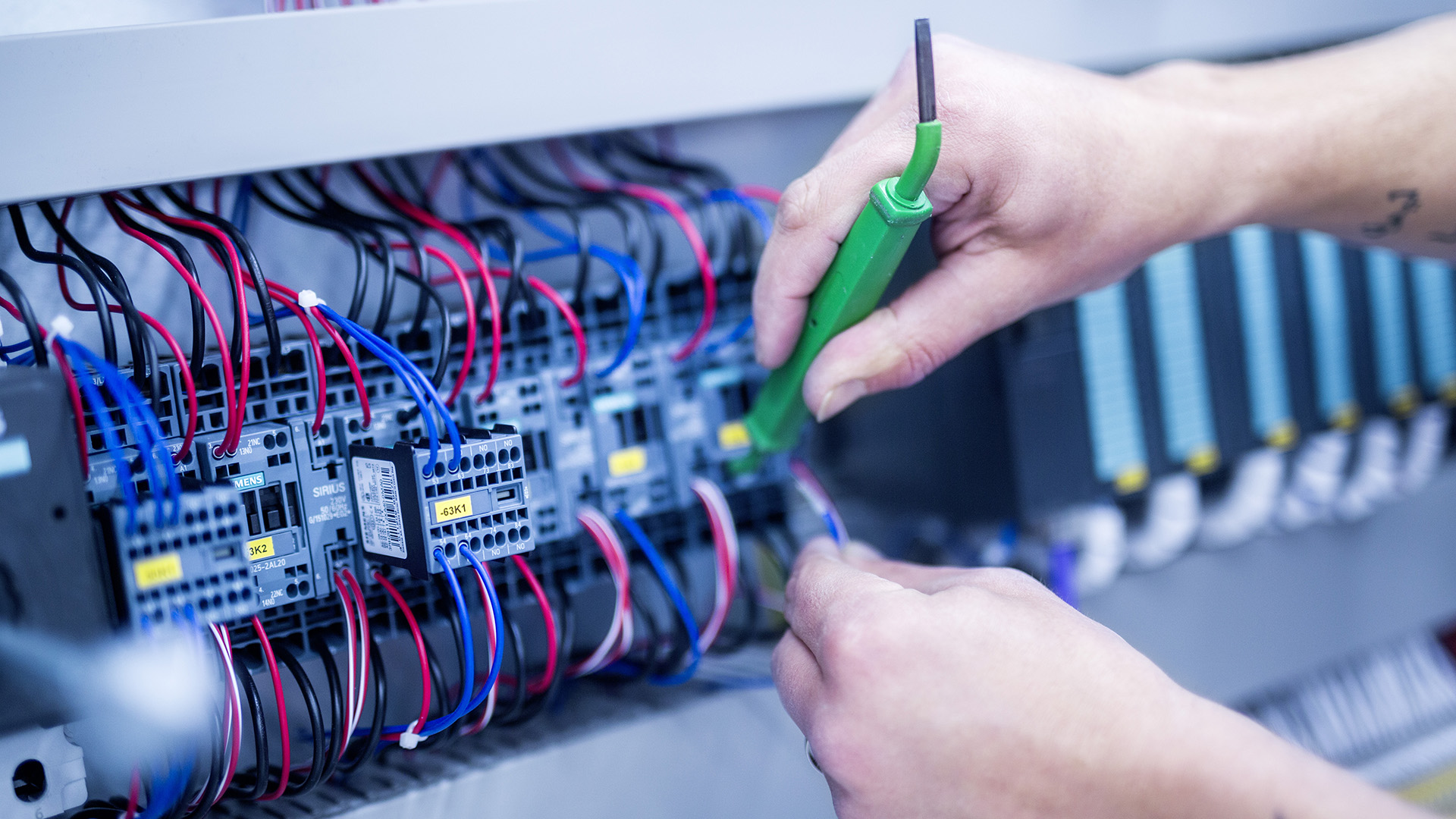

The Siemens S7 PLC controller with touch panel, which has always been an integral part of the L&R Kältetechnik product range and which provides many functions, such as log data recording, process visualisation, trend display, remote maintenance, interface connection and GPS location, helps here. Before the container is delivered to the customer, an orientational mapping of the hot spots is carried out. Since a homogeneous temperature distribution was already ensured beforehand by constructive measures, the spatial temperature gradient is< <2 K. Subsequently, further qualification work is carried out to ensure GMP-compliant execution.

For (mains-independent) quality assurance, customers’ temperature monitoring can, of course, be realised by separate monitoring. Lockable grommets for the PI probe cables are provided. Access control and/or video surveillance is also available as an option. The implementation of an audit trail licence helps with allocating process adjustments.

A wide range of customisation options leaves nothing to be desired

If the standard variant is already equipped with the most important features, further customised equipment can be supplied. If the container has to be moved – whether on the road, on water or in the air – integrated power generators can be provided for cooling during transport.

The container is available as a 20′ or 40′ ISO sea container. Depending on requirements, the footprint can be optimised with special dimensions. However, there is always at least 15 m3 available at 20′ (6 m).

The interior design adapts to the application. Thus, pallet storage spaces are possible as well as shelves and/or drawers for different container sizes. Clean room conditions can be met if the interior is made from stainless steel sheets free of dead space (if necessary with a fully welded base). The 200 mm thick insulation for the cold room panels used ensures a low coefficient of thermal transmittance, which has a beneficial effect on the temperature holding time and energy requirement. A ramp is available for access at ground level. A changing room or manipulation area can be seamlessly connected to the container. FDA approval for materials in contact with the product is also possible.

The goal: The highest possible availability

Our ultra-low temperature units are manufactured for your specific requirements. We focus in particular on a very high degree of availability. The following points guarantee the required operational safety:

Use of components from renowned manufacturers

- Use of components that are largely in stock worldwide

- Excellent “Made in Germany” manufacturing quality

- Remote maintenance options

- nvolvement and support from the local refrigeration company (if desired) or an L&R partner company

- Customer or application-specific service and maintenance concept

- Technical support provided around the clock by competent staff (in case something unexpected happens)

You can rely on 30 years’ experience with L&R cascade technology for low temperature applications!

It is possible to rent out these facilities!

Your advantages

- Airlock (pre-cooling room -20 °C for effective reduction of humidity)

- Fully redundant system with double refrigeration and control technology

- Constant monitoring of temperatures

- GMP, fully qualified (DQ, IQ, OQ, PQ)

- TÜV certified/ISO 9001:2015 accredited

- Numerous options available, e.g. pre-freezer, emergency power generator, special dimensions, shelving systems

- 24/7 hotline

- GPS locator

Mobile pharmaceutical warehouse for COVID-19 vaccine

L&R Kältetechnik

Since 1991, L&R Kältetechnik has stood for reliable refrigeration technology with a focus on environmentally friendly, energy-conscious use of high-performance, high-quality refrigeration systems.

Even before the company was established, the company founder, Burkhard Rüßmann, developed the first 3-stage cascades for rubber deburring at temperatures of -110 °C. This quickly developed into further concepts for the medical and pharmaceutical industries, as very low temperatures are also required here – mostly -80 °C.

An idea has been transformed a globally active company. In close collaboration with customers, we develop overall concepts that make a sustainable contribution to the company’s success.

Our holistic concept enables a particularly high vertical range of manufacture. Combined with 24/7 service, we are extremely easy to reach.

We look forward to working on your project!

30 years of experience give you the edge in new challenges

This is how long L&R Kältetechnik has been developing concepts for ultra-low temperature applications. This is how long L&R Kältetechnik has been developing concepts for ultra-low temperature applications. They can be used to store vaccine sera (vaccines), blood plasma, human biological agents, sample material, chemical substances, reserve samples, stem cells, genomes, bacteria, bone marrow, biomedical materials, compounds, preparations, batches, drugs and medicines.

The fully autonomously operating ultra-low temperature containers are air-cooled, so only a power connection is needed for operation. Even if the power should fail, the optional emergency power supply or even nitrogen emergency cooling (LN2) offers maximum safety.

In direct comparison, frequently used laboratory freezers have significantly higher operating costs, use more floor space and have a high demand for (re)calibration/(re)qualification, owing to their principle of operation.

The details make the difference

With a temperature difference of over 100 K between the external environment and the inside of the refrigerated container, it is easy to imagine that the direct influence on the stored product when the door is opened, without a pre-cooling room that works as an airlock, so to speak, has an undesirably high impact on the quality of the goods.

In addition, at a temperature of -20 °C, the airlock causes a high level of air dehumidification, so in the -80 °C range, on the one hand, the defrosting capacity and therefore the heat input is reduced and, on the other hand, the typical freezing effects (such as slippery floors and icy fans) are reduced. In order not to expose sensitive, expensive goods to any danger, redundant systems are used as standard. Therefore, if a malfunction occurs within a refrigeration circuit or the associated control system, the system automatically switches to the second system.

The Siemens S7 PLC controller with touch panel, which has always been an integral part of the L&R Kältetechnik product range and which provides many functions, such as log data recording, process visualisation, trend display, remote maintenance, interface connection and GPS location, helps here. Before the container is delivered to the customer, an orientational mapping of the hot spots is carried out. Since a homogeneous temperature distribution was already ensured beforehand by constructive measures, the spatial temperature gradient is< <2 K. Subsequently, further qualification work is carried out to ensure GMP-compliant execution.

For (mains-independent) quality assurance, customers’ temperature monitoring can, of course, be realised by separate monitoring. Lockable grommets for the PI probe cables are provided. Access control and/or video surveillance is also available as an option. The implementation of an audit trail licence helps with allocating process adjustments.

A wide range of customisation options leaves nothing to be desired

If the standard variant is already equipped with the most important features, further customised equipment can be supplied. If the container has to be moved – whether on the road, on water or in the air – integrated power generators can be provided for cooling during transport.

The container is available as a 20′ or 40′ ISO sea container. Depending on requirements, the footprint can be optimised with special dimensions. However, there is always at least 15 m3 available at 20′ (6 m).

The interior design adapts to the application. Thus, pallet storage spaces are possible as well as shelves and/or drawers for different container sizes. Clean room conditions can be met if the interior is made from stainless steel sheets free of dead space (if necessary with a fully welded base). The 200 mm thick insulation for the cold room panels used ensures a low coefficient of thermal transmittance, which has a beneficial effect on the temperature holding time and energy requirement. A ramp is available for access at ground level. A changing room or manipulation area can be seamlessly connected to the container. FDA approval for materials in contact with the product is also possible.

The goal: The highest possible availability

Our ultra-low temperature units are manufactured for your specific requirements. We focus in particular on a very high degree of availability. The following points guarantee the required operational safety:

Use of components from renowned manufacturers

- Use of components that are largely in stock worldwide

- Excellent “Made in Germany” manufacturing quality

- Remote maintenance options

- nvolvement and support from the local refrigeration company (if desired) or an L&R partner company

- Customer or application-specific service and maintenance concept

- Technical support provided around the clock by competent staff (in case something unexpected happens)

You can rely on 30 years’ experience with L&R cascade technology for low temperature applications!

It is possible to rent out these facilities!

Your advantages

- Airlock (pre-cooling room -20 °C for effective reduction of humidity)

- Fully redundant system with double refrigeration and control technology

- Constant monitoring of temperatures

- GMP, fully qualified (DQ, IQ, OQ, PQ)

- TÜV certified/ISO 9001:2015 accredited

- Numerous options available, e.g. pre-freezer, emergency power generator, special dimensions, shelving systems

- 24/7 hotline

- GPS locator

Mobile pharmaceutical warehouse for COVID-19 vaccine

L&R Kältetechnik

Since 1991, L&R Kältetechnik has stood for reliable refrigeration technology with a focus on environmentally friendly, energy-conscious use of high-performance, high-quality refrigeration systems.

Even before the company was established, the company founder, Burkhard Rüßmann, developed the first 3-stage cascades for rubber deburring at temperatures of -110 °C. This quickly developed into further concepts for the medical and pharmaceutical industries, as very low temperatures are also required here – mostly -80 °C.

An idea has been transformed a globally active company. In close collaboration with customers, we develop overall concepts that make a sustainable contribution to the company’s success.

Our holistic concept enables a particularly high vertical range of manufacture. Combined with 24/7 service, we are extremely easy to reach.

We look forward to working on your project!

Walk-in warehouses for the pharmaceutical industry

Walk-in warehouses for the pharmaceutical industry

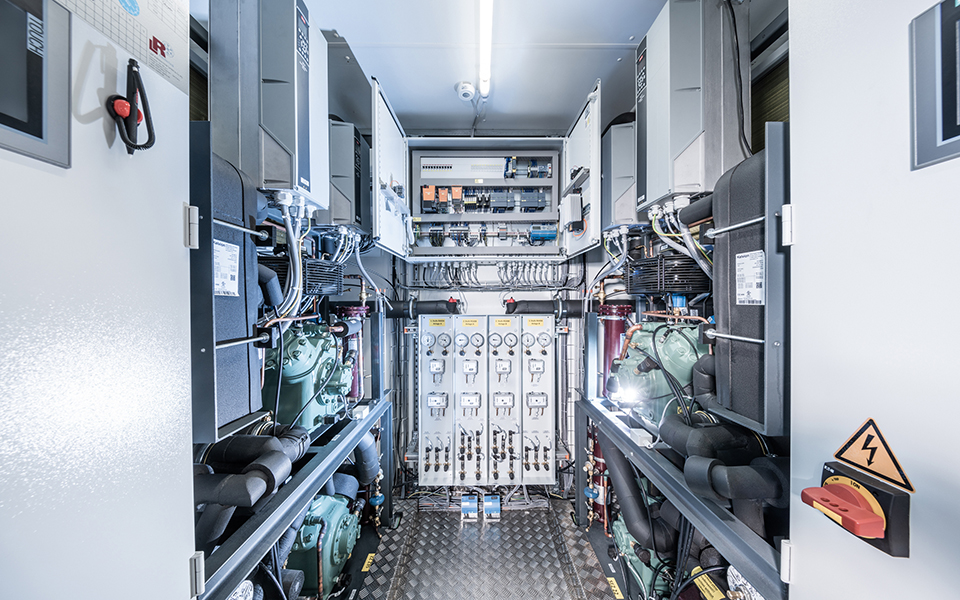

In the pharmaceutical industry, laboratory refrigerators or freezers are often used to store active ingredients or end products at temperatures of -80 °C. Depending on the application, it is significantly more energy-efficient to set up an indirectly accessible deep-freeze warehouse consisting of 20 to 40 cabinets, if necessary, with redundant refrigeration and electrical engineering in a GMP-regulated manner (qualifiable). In addition, this method prevents individual cabinets from icing up.

As a complete solutions supplier, L&R designs and builds walk-in warehouses that not only save energy and space, but also guarantee very high availability of the required low temperatures in addition to offering access controls, optimised control systems and individual adjustment of the ambient temperature.

Do you need advice or do you have a question?

Just send us an

In the pharmaceutical industry, laboratory refrigerators or freezers are often used to store active ingredients or end products at temperatures of -80 °C. Depending on the application, it is significantly more energy-efficient to set up an indirectly accessible deep-freeze warehouse consisting of 20 to 40 cabinets, if necessary, with redundant refrigeration and electrical engineering in a GMP-regulated manner (qualifiable). In addition, this method prevents individual cabinets from icing up.

As a complete solutions supplier, L&R designs and builds walk-in warehouses that not only save energy and space, but also guarantee very high availability of the required low temperatures in addition to offering access controls, optimised control systems and individual adjustment of the ambient temperature.

Do you need advice or do you have a question?

Just send us an