When sinking shafts for new mining projects, freezing technology is being used more and more frequently, because freezing the ground facilitates and accelerates the advance of the borehole. L&R Kältetechnik GmbH & Co. KG, working for the Russian potash mining industry, has developed and built a refrigeration system with a capacity of 3,600 KW, and which cools cold brine to an inlet temperature of -38 °C.

Freezing the ground is a sophisticated method to make shaft construction easier. Groundwater no longer needs to be continuously pumped out, there is less resulting dust, and this method allows for more control over the drilling. Thyssen Schachtbau GmbH has extensive experience with this method and commissioned L&R Kältetechnik GmbH & Co. KG to implement it for a mining project in Russia.

Potash salts are mined in the Perm region and processed into fertilisers by the local chemical industry, among other things. Thyssen Schachtbau was tasked with sinking two new shafts into the ground, each 7.50 metres in diameter and several hundred metres deep. In preparation, smaller, 270-metre-deep holes were initially drilled around the future shafts. In these holes, pipelines were laid, through which cold brine flows at an intake temperature of -38 °C. This freezes the soil and makes drilling the shafts significantly easier.

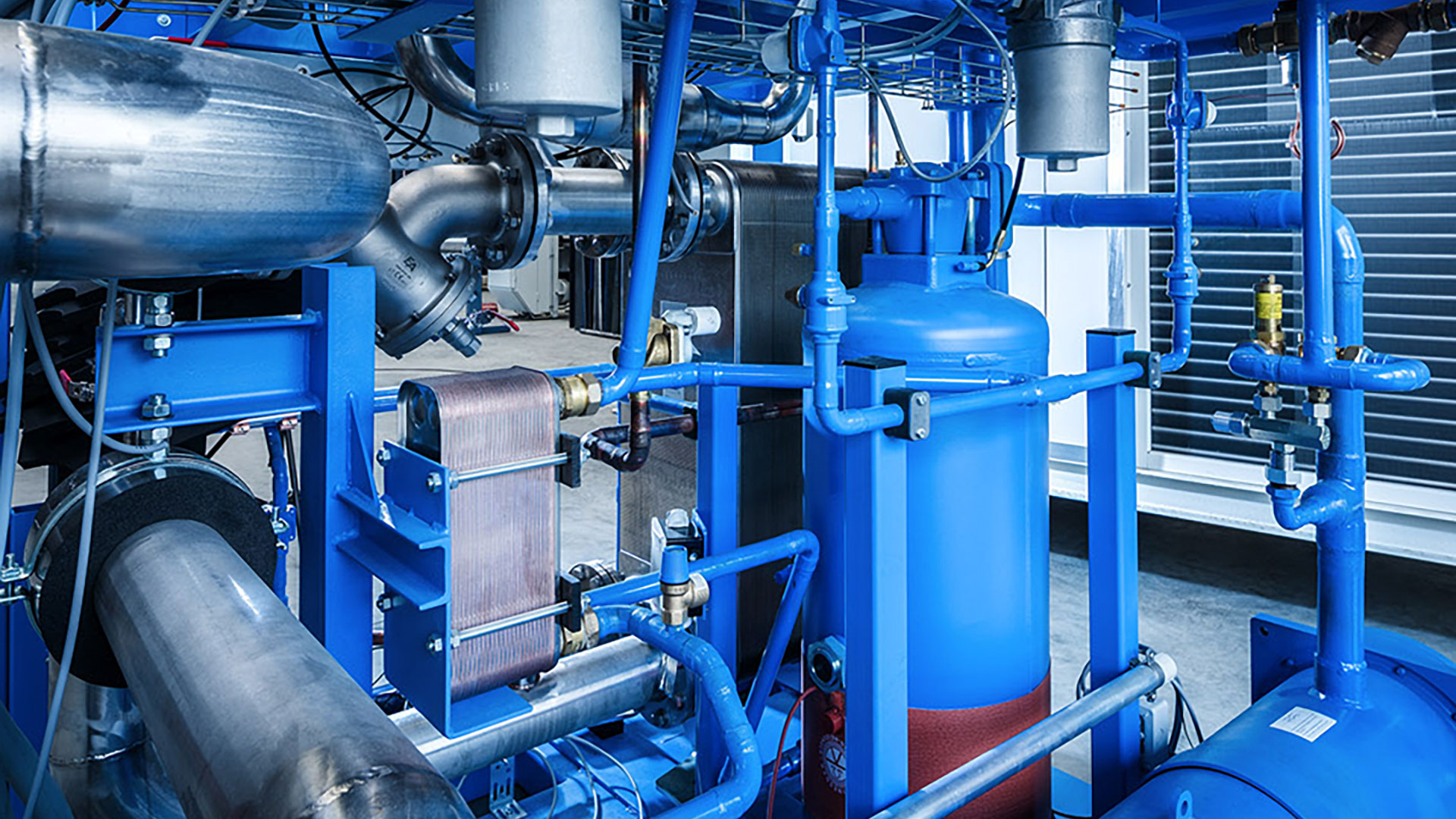

With a total cooling capacity of 3600 kW, the refrigeration plant planned by L&R utilises the refrigerant R507A, which is neither toxic nor flammable and thus offers a high degree of operational safety. It also features a high specific cooling capacity and is well suited for deep-freeze applications. Tyfoxit F50 is used as a coolant.

Rather uncommon is the use of dry, air-cooled condensers instead of the more commonly used wet cooling towers. This concept proposed by L&R offers the advantage, to name just one, that the cooling water does not have to be treated and that there is no risk of freezing, even at very low ambient temperatures in winter.

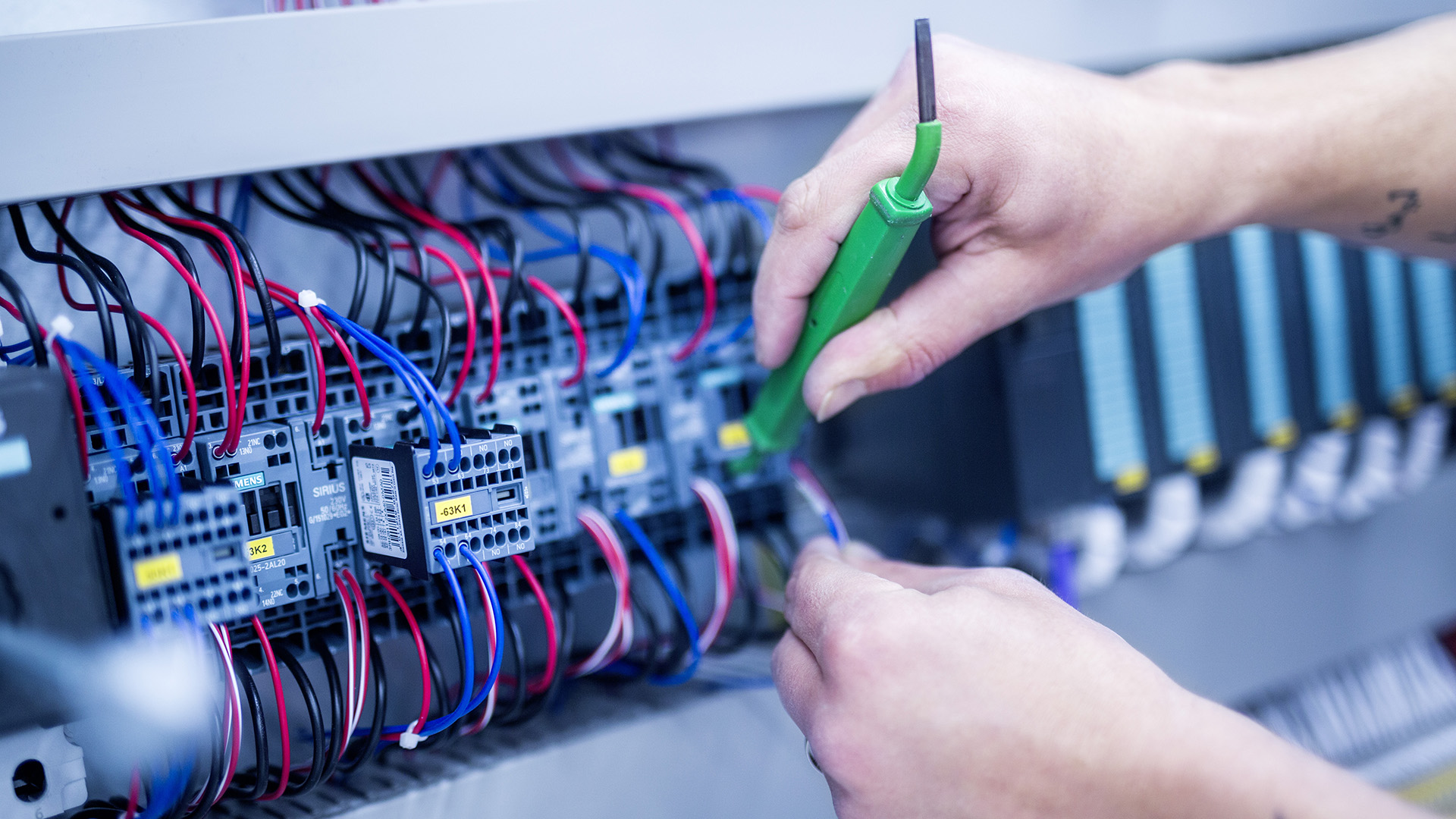

The efficiency of this refrigeration system is optimised by the “VariKon” controller. It adjusts the condensing temperature to actual outside temperatures, which creates the potential for considerable savings, especially at low temperatures. The modern, semi-hermetic Bitzer screw compressor also contributes to energy savings. Its output can be continuously adjusted, ranging from 50 to 100%.

L&R was able to prove in advance that this rather unusual concept is highly efficient in terms of energy and, at the same time, guarantees a higher level of safety as well as lower maintenance requirements. The systems were pre-assembled in containers in Sundern and installed on site with relatively little effort.

After three months of operation, the soil was frozen enough that the actual shaft construction could begin. Now, the ground freezing system keeps the temperature of the soil below freezing for the entire two-year construction phase and thus fulfils the crucial requirement for quick, dust-free and safe shaft construction. A remote monitoring system allows L&R to remotely monitor the system and, if necessary, to act quickly in case of faults.

Sector

Specialised civil engineering

System solution

Compact chiller