CHEMICAL-FREE COOLING SYSTEM CLEANING

CHEMICAL-FREE COOLING SYSTEM CLEANING

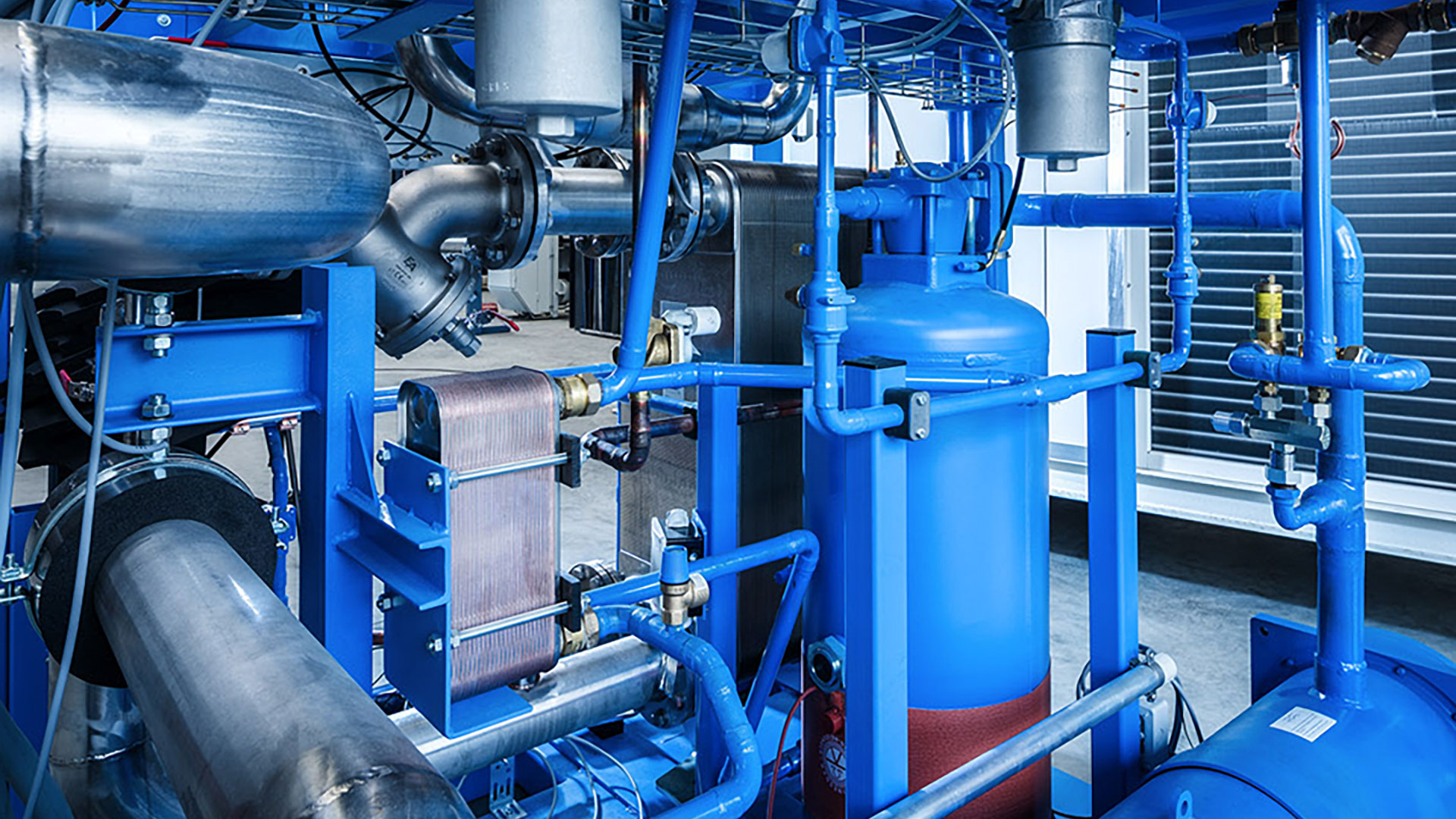

Water treatment only makes sense if the cooling circuits are clean. The COMPREX® pulse rinsing method developed by Hammann GmbH offers an environmentally-friendly option for cleaning and maintaining cooling systems.

The mechanical COMPREX® process removes biofilms and deposits from pipes, heat exchangers and other apparatuses by means of specifically controlled compressed air pulses.

Basic cleaning – usually on an ad hoc basis – upgrades existing facilities to return them to the condition they were in at the start of operation.

Regular or preventive use of COMPREX® cleaning helps to maintain the functionality of the systems and extend their useful life.

With the advantages mentioned, the process offers an excellent cost-benefit ratio.

Basic cleaning ensures that the initial condition is restored. Preventively applied COMPREX® cleaning for maintaining plants and piping systems requires little downtime. Cleaning with COMPREX® during ongoing plant operation is a particularly economical solution.

The success of COMPREX® cleaning can essentially be measured on the basis of the heat transfer or the system characteristics. These characteristics can also be used for condition assessment and thus indicate when the next cleaning is required.

In case of very short cleaning intervals, it may make sense for the user to purchase a COMPREX® unit adapted to the local conditions.

The consequence:

- Typical examples of applications for this process in the industrial sector are:

- fluid-carrying systems in general

- flow and return of main circuits

- mould and machine circuits for plastic injection moulding machines as well as in the field of extrusion

- cooling circuits and heat exchangers for industrial refrigeration systems

- other cooling systems with plate and tube bundle heat exchangers

The procedure at a glance:

- individual pre-planning

- determining the cleaning sections with feed-in and feed-out points

- introducing the COMPREX® pulses

- generating cleaning-effective water and air blocks

- removing and reliable discharging of deposits

- turbidity monitoring

Advantages:

- purely mechanical using compressed air and water

- geometry-independent for fittings, apparatus or branched systems

- scalable in terms of length and diameter

- no dismantling

- short downtimes

- low water consumption and thus low waste water volume

Benefit:

- clean systems as the basis for effective water treatment

- improved cooling capacity and hydraulics

- increased process reliability

With the advantages mentioned, the process offers an excellent cost-benefit ratio.

Basic cleaning ensures that the initial condition is restored. Preventively applied COMPREX® cleaning for maintaining plants and piping systems requires little downtime. Cleaning with COMPREX® during ongoing plant operation is a particularly economical solution. The success of COMPREX® cleaning can essentially be measured on the basis of the heat transfer or the system characteristics. These characteristics can also be used for condition assessment and thus indicate when the next cleaning is required. In case of very short cleaning intervals, it may make sense for the user to purchase a COMPREX® unit adapted to the local conditions.

Your contact partner for H₂O technology –

natural water treatment

GREGOR HEIERMANN

WATER TREATMENT SYSTEMS SALES

Phone +49 2935 9652-210

g.heiermann@lr-kaelte.de