Sophisticated plant technology

At NaProFood GmbH & Co. KG in Bruckberg, a refrigeration system is in operation that is probably unique throughout the world. Four refrigeration circuits with four different refrigerants are connected in a cascade system and provide temperatures ranging from -70 to +85 °C.

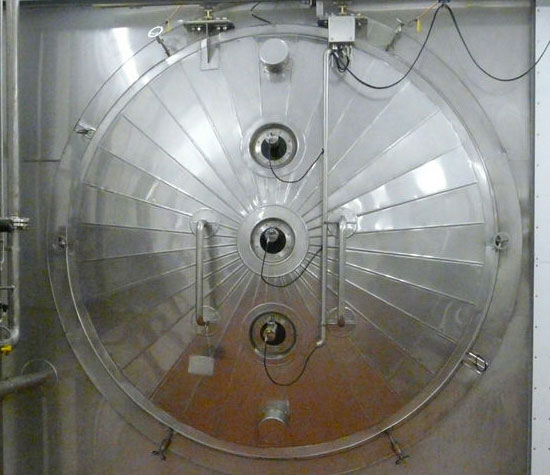

NaProFood GmbH & Co. KG specialises in (freeze) drying of high-quality food and pharmaceutical raw materials. Their systems and processes are used when conventional drying methods do not achieve satisfactory results or when high-quality products are to be dried particularly gently. More and more customers, especially from the food and pharmaceutical industries, are taking advantage of this offer. The freeze-drying systems used in the new plant in Bruckberg were individually developed. Refrigeration technology plays a major role in plant engineering, because frozen food must be kept at a precise temperature during the process.

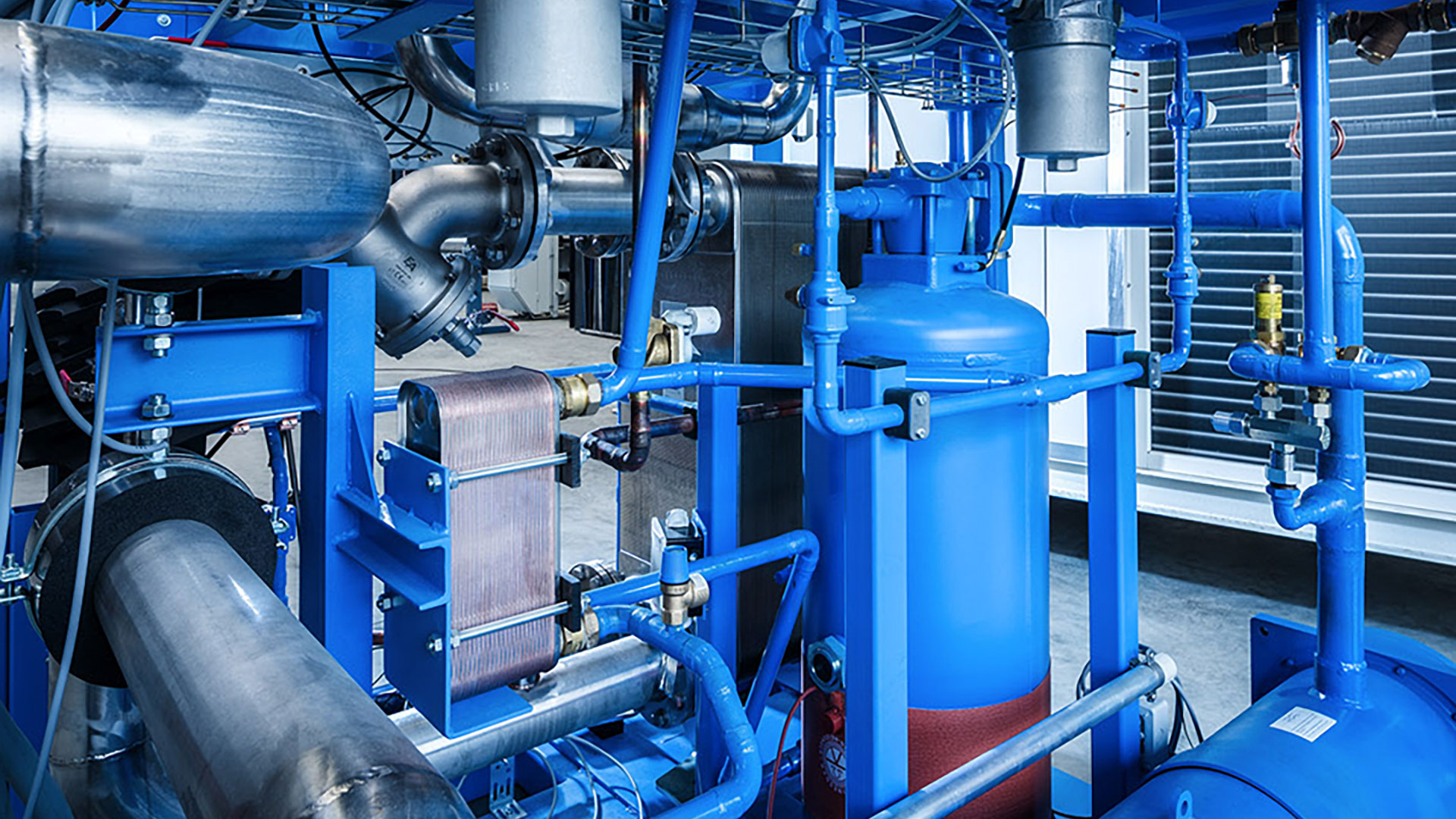

Cooling and heating in different temperature ranges

On behalf of the general contractor, L&R Kältetechnik developed a refrigeration system with two refrigeration circuits. The two low temperature refrigeration systems, utilising the refrigerants R 507 and R 23, supply process cooling both for the cooling coils in the so-called ice condenser (in which the water separated out of the process condenses) and for the parallel plate heat exchanger for the product chamber circuit. There, a thermal oil circulates through plate-like cooling or heating elements, which are arranged directly under the trays in which the material to be dried is located. Depending on whether heat has to be extracted or added to the process during drying, the thermal oil is cooled by the heat exchanger for the refrigeration plant or heated by a second heat exchanger. The resulting water vapour is sucked into the ice condenser by a vacuum pump and condensed into ice and held there.

Two capacity-controlled refrigeration systems – combined with heat recovery

A frequency-controlled compressor is installed in the low-temperature stage for the system, as the refrigeration requirement decreases continuously during the course of the drying process. In the last third of the drying process, the refrigeration system is even switched off completely at times, and the

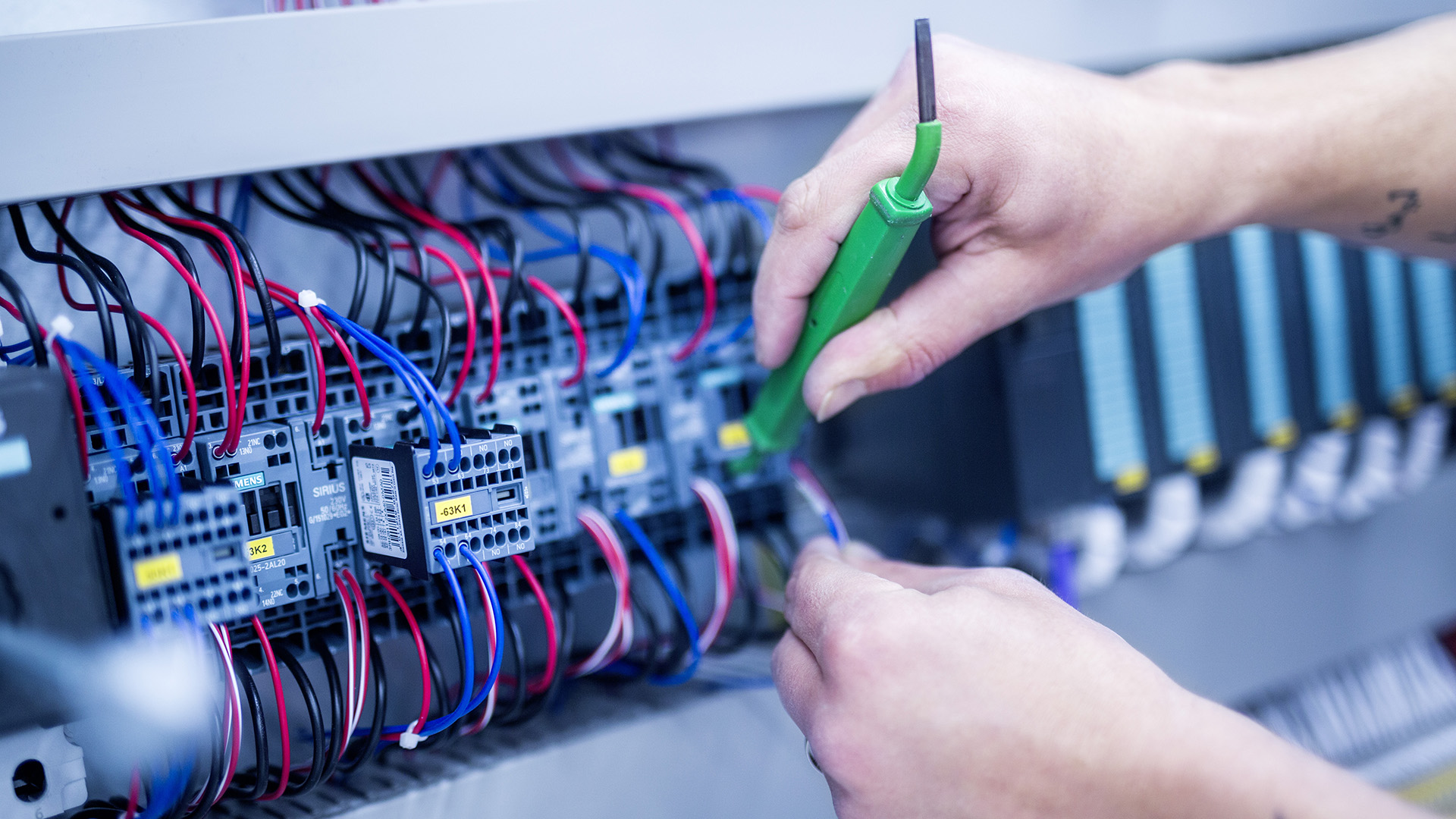

refrigeration buffer capacity of the ice condenser is utilised. The switching on and off of the refrigeration system is controlled by an algorithm integrated in the PLC, which can forecast the condensation demand. This saves energy.

Another special feature of NaProFood’s thermoprocessing technology is that the heat introduced into the refrigerant is used for heat recovery. The heat pumps, which supply the two circuits and are filled with the refrigerants R 134a and R 236fa, provide such large quantities of heat that NaProFood can cover over 80% of its thermal process energy requirements in normal operation.

A unique (refrigeration) plant

In summary, you could say that this is a unique thermo-processing plant that supports a fascinating procedural process. Four refrigeration circuits with four different heat transfer media provide cooling and heating ranging from -70 to +85 °C. They have been integrated into a highly complex overall process that also incorporates other energies, such as compressor exhaust heat. The control technology developed and programmed in-house by L&R Kältetechnik ensures very precise temperature control at all temperature levels.

Sector

Food industry

System solution

Compact chiller